|

|

omponents used for music reproduction (audio) are quite "specific" electronic devices, because during their design phase many more conditions have to be fulfilled than for electronics not intended for audio. When we properly build e.g. an intercom, it will work, but if we make a mistake somewhere - it will not. If we properly build an amplifier and it will work, it does not necessarily mean that it will sound good. So, although it works it won’t fulfill its role. omponents used for music reproduction (audio) are quite "specific" electronic devices, because during their design phase many more conditions have to be fulfilled than for electronics not intended for audio. When we properly build e.g. an intercom, it will work, but if we make a mistake somewhere - it will not. If we properly build an amplifier and it will work, it does not necessarily mean that it will sound good. So, although it works it won’t fulfill its role.

In audio equipment we can often see specially selected components (because e.g. capacitors from different manufacturers sound in different ways) and custom solutions (manufacturers own patents), which is why the design of well-sounding audio devices takes so much time. Their sound is also not always adequate to measurements performed on them (sometimes a great sounding device comes up very average in the measurements and vice versa), and the combination of seemingly the same electronic components can often give different sound effects. This is the real world, other than the computer-testing environment where you can isolate and simulate the behavior of individual components or parts of the design, without changing the rest. Therefore, the "almost perfect copies” made in the DIY audio world are not really copies, but better or worse completed designs based on standard wiring diagrams. The great characters of the audio world are not afraid of copying them, and sometimes even publish their best designs diagrams, but without the guidance of their assembling. Why is this happening?

Designing of audio equipment is really the fight for the least distortion in sound reproduction or, if you prefer, showing as many advantages as possible, hiding flaws and sketching by the designer an intended end result. Obtaining the "desired" sound is always the result of many attempts, correcting the values of individual items, making changes in the circuit-board layout, or its location in the chassis, etc., etc. All components work together to create a new quality. When one of the 100 elements is wrong, it will affect the others (change their operating characteristics) and disrupt their proper operation. It's a kind of a domino effect.

We also need to realize that it is not about changes in the order of 10 or 20%. Not even one percent but only one part mille will often be important. For example – moving a capacitor on the circuit-board by a few centimeters (or an inch) closer to the grounding will trigger changes in the sound, and yet the wiring diagram (as well as measurements and computer simulations) won’t show any change. After all, it’s "only" one ten-thousands of Ohm of circuit path resistance which is, however, easily perceptible to the human – not to mention the audiophile – ear. It’s hard to imagine how precise the sense of hearing is!

All of electronic components are located in the electromagnetic field, they co-create it, receive it, and are somehow a part of it. Any disturbance of this field affects the operation of these components, the "quality" of their work with others and, as a consequence, the level of distortions and the final sound effect of the device. Therefore, it is very important to separate the unit from the external conditions, and to create the correct "isolation" for it. The fight against electromagnetic interference must also occur inside the chassis. The largest of magnetic field generators inside the device – the transformer – includes within its influence all system components. Alternating current (AC) with a frequency of 50 or 60 Hz (USA, Japan) produces a huge amount of distortion.

And so we came to VIBRATIONS. Almost all of us have heard the buzz, and sometimes even the whirr of the transformer. Its elements are not rigidly connected to each other. The alternation of the electric field causes changes of the magnetic field, and you can imagine that the individual turns of wire in the transformer “dance like the strings". The frequency of 50/60 Hz is also perfectly audible by humans and perceptible as the vibrations. These vibrations are transferred to the rest of the chassis. In the case of tube amplifiers, to the tubes, disrupting the path of the electron beam between the cathode and the anode. In CD players – to the laser beam, affecting the error correction system. Imagine that 50 or 60 times per second, someone tells us to jump up and down slightly and on top of that to read a newspaper in such conditions...

Next to the transformer vibrations are those from the outside - such as from unstable wooden floor and most of all vibrations coming from the bass speakers when we listen to loud music. In extreme cases, when the laser beam of the player is showing its age, we can even see that at loud listening it loses track and jumps to another location of the recording. To the laser head it is like an earthquake to the building. When we feel the music by "whole our body", imagine what happens to the turntable needle, which is sensitive to tiny grooves in the record (?).

The CD is able to rotate more than 500 times per minute, DVDs or Blu-ray up to several times more. Mass production of disc rotating engines, as well as hundreds of millions of CD’s is unable to provide the perfect distribution of weight - almost none of the CDs is properly balanced. When we "load" a CD to the player, it is pressed by a small disc, often made of plastic, imposed automatically by a little spring. Who opened the casing of the player certainly watched the head follow the path during each rotation of the disc. When the unbalanced weight rotates, centrifugal force is created, the vector of which is attached not to the axis of rotation, but on an eccentric - the whole system begins to vibrate. Error correction system of the player easily deals with these vibrations, but how more accurate would be reading of the disc, if the vibrations were be reduced by half?

For this purpose let's provide the device with an accessory that will help reduce at least partially all vibrations listed above. When we listen to loud music, the device will be less responsive to the “bass kick”, the chassis vibrating under the influence of the transformer will not resonate so strongly, and even the transformer will fell into resonance much harder. The entire system will have more stable magnetic field, less interference will reach the rectifiers, in consequence the power supply will be more stable, electron beams in tubes will be less disturbed, the vibrations of a spinning CD will also be partially suppressed. As a result, the overall level of distortion will be reduced. It is like a change from a "rack wagon" to a car with modern air suspension. That's why all kinds of feet, legs, stands, and finally complex anti-vibration platforms makes sense.

|

Where did the idea for the vibrations absorbing platform come from?

In daily life, every day we have to deal with a variety of "harmful" oscillations and vibrations, which we are trying to fight with.

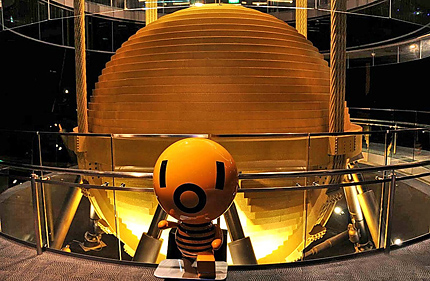

In the second half of the 20th century seismology and seismography has grown markedly. Countries located in areas subject to earthquakes introduced standards specifying how to design buildings that are strong enough to survive even large quakes. Buildings in these areas of the world are built differently than "normal" buildings in the "quiet areas" such as Poland. Among others, they use additional joints in the foundation, more powerful and carefully selected construction materials, and additional elements to help the building survive during an earthquake or hurricane. A great example of the use of such technology is "Taipei 101" skyscraper in Taiwan, built almost on the tectonic ledge, which at the height of half a kilometer can survive an earthquake measuring 7 degrees on the Richter scale and resist hurricanes without damage. Inside this building there is a pendulum several floors high – a large extra mass which helps to suppress vibrations and reduces deflection of the structure during high winds. There is even an observation deck from which you can observe how the pendulum moves sometimes up to several meters in relation to its initial position.

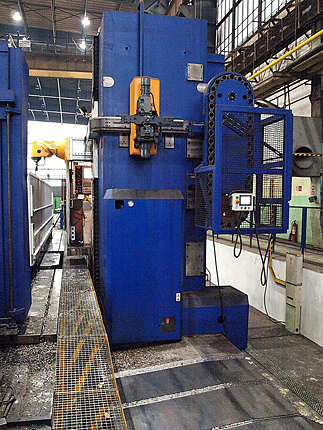

In the heavy industry during machining of heavy elements a powerful processing stations are used - lathes, milling machines, etc. The rotation of the elements of these machines along with machined structures on them causes powerful vibrations that can sometimes cause subsidence and destruction of the foundations for the machines. Designing the foundation is distinct, important field of knowledge. On the basis of the equipment, their possible loads and engine speeds, resonances that arise in the foundation are defined. The result of the calculation is required later in the foundation of the weight distribution, the measurements and the schematic design for the machine set to not fall in excessive vibration. A properly designed foundation is an "anti-vibration platform" for this device. To partially suppress machine vibration during their work, in some cases, a powerful subwoofers with a power of several kilowatts can be applied. Subwoofers are placed next to the machine and generates a corresponding vibration frequencies, accordingly displaced in phase.

When we bring the above described and similar ideas and technologies from the "macro world" to the world of audio equipment and we use them skillfully, we’ll create anti-vibration device that will affect positively to the sound of our audio system.

Why every part of the platform is important?

There are several ways of fighting with vibrations and resonances. Every substance having a mass also has dependent on it vibration frequency. By changing the weight of the body, we’ll change the frequency at which it falls into resonance.

Different materials have different hardness, internal structure and other properties of transmission or absorption of vibrations (energy accumulation). For example - hard steel is a very good "relay" of vibration, while rubber will cumulate and suppress these vibrations very well. This property is defined as the damping factor, which depends on the density and internal structure of the material.

Parts made from the same material but with different external dimensions will also have different resonance frequencies. Not without significance is the internal structure of the material - glass with amorphous structure will behave quite differently to materials with crystal structure, such as metals or minerals.

By the proper choice of materials we can influence the transfer and the damping of specific frequency - such as the vibration frequency of the mains transformer. It should be remembered, however, that it is impossible to „adjust” vibration damping for one of the frequencies. Any material, or a combination of several different ones, will operate at wider frequency range (not one specific), and also to the frequency of a quarter, half, and an octave higher and, respectively, for the next quarters, halves and full octaves above (difference of an octave is frequency doubling). Simplifying - if we "set up" the resonance of the anti-vibration platform to exactly 50 Hz, it would operate well at frequencies of 100, 200, 400 and 75, 150, 300, and at all intermediate, but weaker. It could also be that it would act almost as much on the frequencies on which we don’t want to influence.

We can often hear that the material causes these or other changes in the sound (it has its own characteristic sound), such as granite, glass, acrylic or wood. In the construction of anti-vibration platform this “sound of material” can be skillfully used, but you can also do it badly and the audio system will sound even worse than before. For example, if we find that an amplifier or DVD player placed on granite slabs with the thickness of an inch (2.5cm) sounds better (decreased resonance of the entire system - its mass has increased), it doesn’t mean that placing it on granite slabs with a thickness of 2 inches (5cm) will double the improvement in sound. Too much weight can in fact cause so strong shift of the resonance of the entire system that ultimately contribute to increasing oscillations in certain frequency ranges, which in turn will impair the sound quality perceived by us. So it is easy to "overdo it".

Some of the frequencies are very difficult to suppress. In that case we can try to transmit most of them (unfortunately, it will never be fully possible) by using the materials which transfer vibration well (hard). You can also try to isolate the unit from vibration, using the smallest possible area of contact between two parts – a spike with a very small area will transmit less vibration than a plate with a much larger area. For the anti-vibration platform design you can use many different materials, with different mass and dimensions, whose vibration transfer and damping characteristics will work together. The variety of combinations is almost unlimited.

An important factor in designing a vibration absorbing platform is its geometry. Not all audio components are in fact build symmetrically. Transformers are often more to the left or right side of the chassis, the mechanisms are often more at the front, rather than in the center. Resonances are also distributed differently on quadrilaterally-spaced supports (when the device has 4 feet), and differently on the triangle basis. It must also be taken into account.

There are many factors to be taken into account, therefore it is very difficult to build an anti-vibration platform that will properly interoperate with multiple different devices. It will always exhibit a better "fit" with some, and will work worse with others. It is therefore necessary to seek a solution that will eliminate (or mask) as many flaws as possible and to expose the advantages of the configuration.

The best would be such platform design that can "break" or lower the resonance level within the largest frequency range, properly isolate the device from the influence of external vibrations and at the same time skilfully "control" the vibrations generated inside the device.

With all this in mind, I designed the GRAVITY platform. When I was working on it, I tried to use as many of the above written characteristics as I could. I encourage you to test it in your own audio system.

|