|

INTERVIEW KARL-HEINZ FINK

Company contact details: |

|

|

The cover of “High Fidelity”, December 2014 (HF | No. 128) with a photo of Hans Theesink taken during a concert at the Audio Show 2014 exhibition The memory triggered off a whole bunch of associations – in 2014, Hans Theessink visited “High Fidelity” and gave a fantastic concert during the Audio Show 2014 exhibition. Another common friend of ours, Matthieau Lattour, the CEO of the Nagra company, also released his album with Dirk – it was a “live” recording, this time one of Leon Russel from the Montreaux Jazz Festival in 2011. Naturally, the concert was recorded on the Nagra T tape recorder (Edel: Content 0208394CTT, “Triple A Series”, 180 g LP, 2013; a coverage of the visit at the seat of the Nagra company can be found HERE). It demonstrates that, in the audio world, people with similar tastes, beliefs, sensitivity, etc. join together to form different constellations, a bit like crews forming jazz bands, often for the purpose of recording one album only. You may have already noticed that Mr Karl-Heiz is a versatile person with a lot of interests. On the one hand, he knows Dirk through his birthplace – Bohum and, on the other hand, thanks to the fact that he used to write for German audio magazines, mainly for “Stereo”. When he was a teenager, he constructed loudspeakers and sold some of them to his acquaintances. Untypically for a German person, his point of reference were British constructions, including ones manufactured by the Harbeth company. But, as he adds, his mentor was Ted Jordan, the owner of the ALR/Jordan company, i.e. a German firm (one from Essen – the city where the seat of the Fink Audio-Consulting company is located). Quite early, he started working as a consultant. It is a profession known in every field, including the audio domain. A large company hires someone to carry out a single project which it then sells under its own name. The name of such a consultant is usually given (see the fashion industry) but equally often nothing is said about him or her. As it seems, the aim is for the company not to tarnish its image. It is assumed in specialized fields that the manufacturer is also the originator and that they actually carry out the project. If they need some outside help, it means that they are “not coping well”.

The Naim Ovator S800 – one of the constructions made by people from Fink Audio Consulting Reality is a bit more complex. That is why Mr Karl-Heinz Fink and his Fink Audio-Consulting company are one of the most (un)known chapters in the history of audio. It is because the designs of many important series of loudspeaker columns, mainly for British, German and Japanese companies, come from Essen. Among others, firms such as Tannoy, Yamaha, Q Acoustics, Boston Acoustics, Castle, Denon and Marantz have used the company’s services. One of the constructors that it employs is Mr Lampos Ferekidis, who once worked on the NXT project and whose experience proved valuable for the Ovator S-800 project (with an NXT panel) for the Naim company and, right afterwards, for the car-audio system for Bentley cars (by Naim). In 2016, Mr Karl-Heinz came out of the shadow, offering the enormous WM-3 loudspeakers. Their design included everything that the FinkTeam company, established for the purpose, had to offer. These were enormous, three-way, four-driver loudspeakers. The midrange/tweeter section had the form of D’Appolito arrangement, i.e. there were two midrange drivers on both sides of the tweeter. Below, there was an enormous 15-inch woofer.

The FinkTeam WM-4 loudspeakers during the High End 2017 exhibition in Munich All of these drivers were very characteristic. The tweeter was an AMT driver based on Dr Oscar Heil’s patent. The midrange drivers had characteristic flat membranes – these were FMWD (Flat Membrane Wide Dispersion) drivers based on the NXT technology. The woofer resembled units used in Pro (stage) loudspeakers – it had a paper membrane, textile surround and concentric “circles”. A year later, during the High End 2017 exhibition in Munich, their development version, the WM-4 model was presented. We saw something equally exciting then – Mr Fink’s latest design, the Borg model. This loudspeaker is to include distilled WM-4 solutions in a much smaller form and at a more affordable price. The presentation attracted a lot of interest from the press and visitors. It was repeated during the Audio Video Show 2018 exhibition in Warsaw and it attracted the crème de la crème of the European (and not only European) audio press. There was everyone who has any significant importance in this world. The loudspeakers, with Thrax Audio electronics and the Kuzma Stabi R turntable delivered simply excellent sound. Let us add that it was also largely thanks to wonderful setup done by the RCM company - Mr Karl-Heinz couldn’t praise it enough. A natural consequence of such wonderful performance was the Best Sound • Audio Video Show 2018 award given by our magazine.

The FinkTeam BORG loudspeakers during the Audio Video Show 2018 exhibition The loudspeakers sounded very much like what I hear every day in my reference system. So, right after the exhibition, Mr Roger Adamek (the company’s distributor for Poland) and I arranged for their test that you will find in this issue of “High Fidelity” (HF | No. 178). In order to make everything go the way it should, we invited their constructor to Cracow. Making use of this opportunity, I asked him about a few things connected with the design of the Borg loudspeakers. You will find the interview below. KARL-HEINZ FINK is interviewed by Wojciech Pacuła accompanied by Roger Adamek, the owner of the RCM distribution company.

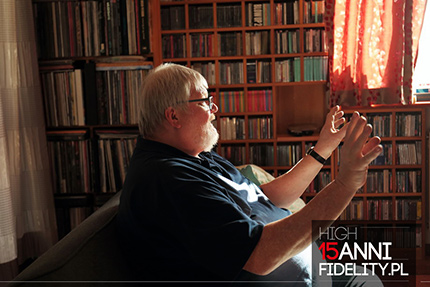

Mr Karl-Heinz next to the Borg loudspeakers in the “High Fidelity” reference system WOJCIECH PACUŁA: When exactly were your companies founded? What was FinkTeam’s debut loudspeaker? Which of the projects carried out for external companies has brought you the most satisfaction? I’ve seen your presentation in Warsaw at the Audio Video Show 2018 exhibition and I was very impressed with your Borg loudspeakers. I was even more impressed because these are two-way speakers. And there are so many issues with two-way speakers having such a big woofer. How do you deal with them? The woofer itself runs flat at 2.3 KHz. But, again, the crossover is set at 1,600 Hz and if you measure out of axis, you can see that the whole response slowly goes down there. It is sensible to design a loudspeaker to go a little bit down out of axis. And if you compare this loudspeaker with one having a conventional 25 mm dome tweeter, for example, you can see that frequency response at the crossover point in the conventional one first goes down a little, then goes up and remains higher, and then goes down again. The overall curve measured for our loudspeakers is a slightly falling one. That makes them it a bit easier to use in different listening rooms. The woofer seems to be a very conventional one, like one from the 1960s or 70s. |

OK. But this implies high sensitivity, which is not the case here. There’s a relatively easy law referring to the dependence of bandwidth on sensitivity. If we want a loudspeaker to go down to 35Hz and we have a cabinet of a specific size, equipped with a specific drive unit, then we get specific sensitivity. If we want to have more bandwidth, e.g. up to 20Hz, we have to sacrifice or compromise sensitivity – that will cost us 2 or 3 dB. If we make a loudspeaker with a driver that allows us to obtain 96 dB, then there’s really nothing below 50 Hz. So, these rules are quite commonly known, but it is crazy that most people think that the values of, for example, 97 dB and 35 Hz given in a loudspeaker specification are true... This is not possible. When it comes to the Borg model, it is not about marketing, but real sensitivity. The crossover consists in two parts, right? Why? I personally don’t like bi-wiring, bi-amping, etc. From my experience, one set of posts is better than two. In Warsaw, I saw the bass-reflex construction that you have used in the Borg loudspeakers. Are you going to patent this technology? Is making your own loudspeakers more difficult that working for someone else? Obviously, these are two different worlds.

We are arranging the loudspeakers – this is a parallel arrangement preferred by Roger Adamek A tough job, isn’t it? It’s hard to survive in the world of audio. And which company does Stephen Harris represent? So, one might say these tasks are easy to carry out (laughs)? Despite its shape, the bass-reflex design, etc., the loudspeaker still looks like a pretty conventional one. Why are we still using the same technologies to manufacture loudspeaker columns as 100 years ago? There’s a lot of progress and development is still unfinished, so we still have a lot to do – look at distortion, for example. In the old days we would say that a loudspeaker is the weakest element of a system, owing to distortion. Distortion measured for the Borg model, for most of the bandwidth and SPL, equals 0.1% and there are a lot of tube amplifiers that have more. We get 0.1% at 90 dB, so if we turn down the volume (and that’s what we normally do), distortion is even lower. So, what direction in loudspeaker production is the most promising right now? The Borg model has a three-part cabinet, doesn’t it? And if you look at the high-end sector, what makes it different from medium hi-fi? Drive units are almost the same. Everyone buys them from Thiel, Accuton, Eaton or Scan-speak and puts them into cabinets. We didn’t want to use a technology which consists in selecting the biggest drivers. We wanted to do it in a slightly different way, based on simulations, calculations and measurement. We have a laser scanner that allows us to scan the surface of such a loudspeaker. We can translate the measurements into sound, using calculations. Returning to our cabinet, it has many different layers, braces and some extra material inside to add some loss. It does not resemble our designs made for other companies. It’s a different technology because I didn’t want to use the old one anymore. So, there’s a lot inside the Borg cabinet that we cannot see on the outside. Is it better to damp or to control vibration?

“Why don’t we toe them in a bit?” – Mr Fink prefers a little more toed-in loudspeakers. If we go back to the BBC loudspeakers for a moment, we will see that they vibrate all the time, but only in the low end and never in the midband. That means we shift problems into an area where they do not sound that bad. If we study what Dr Harwood did at the BBC, we will find out that the solution he developed for the BBC monitors was not the best one, but just the cheapest one. What mattered was the price-quality ratio. That was our starting point – we made use of all the research that had been carried out and tried to do something better, using the latest technologies and more modern materials. So, might one say that these are modern BBC loudspeakers? I can see it’s really big. The first time I saw it, I thought that the midrange drivers are covered with something. Do you remember the first Utopia model by Focal? They had a wooden cover for these speakers, preventing them from being damaged. Is there a plan for something else in the line? I am not sure, though, if we manage to finish it before the exhibition in Munich. However, the next important worldwide show is the one in Warsaw. It doesn’t make any difference to me if I go to Munich or Warsaw. The only problem connected with exhibitions occurs when you have a distributor who has no idea of what he is doing – then things get really difficult. Our distributor for Germany, the Benelux, Switzerland and Austria is a really nice guy with a lot of experience in selling and distribution. However, I need to do the setup. Before a show, we load a truck with room acoustics, we send it out with the rest of our equipment and I go there to do the setup. That happens in many countries, but not in Poland. The RCM crew set the Borg loudspeakers up in a simply perfect manner – I walked in, played a few albums and knew everything was ideal.

Could you now describe the audio system that you use to listen to new loudspeakers? We made the phono stage ourselves. Walter Fuchs, a well-known designer of such devices, is part of our team. It is a symmetrical circuit with current amplification. The line preamplifier was manufactured by the Funk company from Berlin. This is a professional audio element, but it sounds excellent (a test of the Funk Tonstudiotechnik LAP-2.V3 amplifier can be found HERE – Editor’s note). We have also constructed the power amplifier. Let me also add that we use a few Isotek filtering devices: the Titan, Genesis Mosaic and Sigma. Thank you very much for the interview. |

main page | archive | contact | kts

© 2009 HighFidelity, design by PikselStudio,

projektowanie stron www: Indecity

I think that what Mr Karl-Heinz Fink first said to me, having asked for tea and sitting down after we hugged and greeted each other, was: “We have a common friend – Dirk”. He was talking about Dirk Sommer, the editor-in-chief of the

I think that what Mr Karl-Heinz Fink first said to me, having asked for tea and sitting down after we hugged and greeted each other, was: “We have a common friend – Dirk”. He was talking about Dirk Sommer, the editor-in-chief of the